Selective Laser Annealing Enables Higher Monolithic Magnetic Sensor Yields

Suitable for GMR or TMR (Giant or Tunneling Magnetoresistance) Sensors

Magnetic sensors are a rapidly growing technology to help fulfill the promise of a world with intelligent electronic devices in every machine and every pocket. Magnetic sensors can be found in consumer electronics such as rotation sensors and e-compasses in smartphones and virtual reality headsets, in appliances such as linear position sensors and angle sensors for brushless DC motors, and in automotive applications such as power steering angle detection and electronic throttle control. Selective laser annealing enables magnetic processing of monolithic integrated sensors.

Laser annealing for setting the magnetic orientation

Programming GMR and TMR magnetic sensors involves setting the magnetic orientation of the reference (fixed) magnetic layer in the desired sensitivity direction. This programming – also known as pinning – can be accomplished by heating the sensor structure above the magnetic blocking temperature of the antiferromagnetic film that is adjacent to and that normally freezes the reference layer magnetization while applying an external magnetic field large enough to saturate the reference layer in the new chosen direction. Upon cooling in the external field, the saturated reference layer becomes fixed, or pinned, in the programmed direction.

The traditional approach has some major disadvantages

Thermal annealing has traditionally been used to achieve pinning. While this approach can enable batch processing of large numbers of wafers simultaneously, a key disadvantage of thermal annealing is the potential for process non-uniformity (temperature or magnetic field conditions) within wafers, or from wafer-to-wafer in batch processing. Another major disadvantage is the difficulty in targeting different parts of the same wafer for different programming conditions, which is necessary to organize two or four separate sensors within a single sensor chip in standard Wheatstone-bridge configurations to boost sensitivity and improve temperature stability. Multiple-die approaches to solve this problem are expensive and difficult to implement accurately, resulting in limited miniaturization, lower performance, and higher cost.

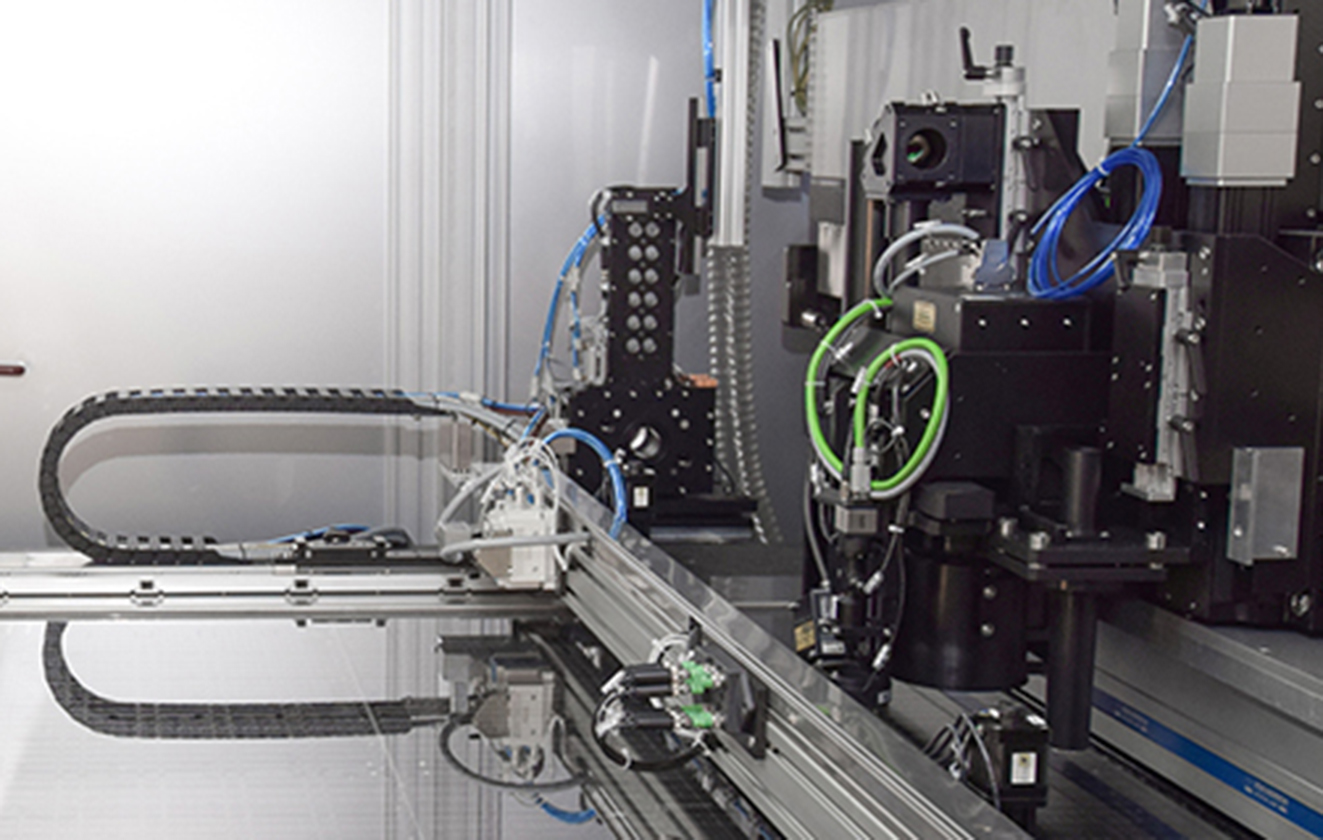

Laser annealing enables the programming of advanced sensors

Selective laser programming of magnetic sensors is a production-approved technology with many advantages. This solution significantly reduces the costs of sensor chip manufacturing by enabling a one-step process. Selective laser pinning is the most efficient technology in terms of cost, throughput, yield, sensitivity, and quality to accurately program magnet sensor devices. It can be programmed for different sensor and wafer designs using a recipe. Both types of sensors, GMR and TMR, can be processed – simply by selecting the appropriate recipe.